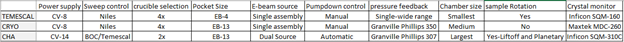

ME02 Cryo-Evaporator E-beam Deposition

Process Data

Control Charts

ME03 Temescal E-Beam Deposition

Temescal 1800 e-beam evaporator is a single-chamber system for the thin-film evaporation. A maximum of four different materials can be evaporated in one pump-down cycle, from the four pocket electron gun. The thickness of the metal is monitored during the evaporation by an Inficon thickness monitor. Substrates up to 4 inches can be attached to the rotating substrate holder. The system does not have substrate heating . The available materials are: Au, Ag, Al, Cr, Ni, Pt, Tungsten and Ti. The vacuum system has been upgraded to a cryo pump.

Process Data

Control Charts

ME01 CHA Mark 50 E-Gun Evaporator

The CHA evaporator is a 3 gun 13 kilowatt cryo pumped e-gun metal evaporator allowing co-deposition by running 2 guns simultaneously. This uses an EB-13 crucible and is used for gold, copper, and chrome evaporation.

Process Data

Control Charts

MS02 Hummer VI Sputter

The Hummer is a sputter system used to coat SEM samples with a thin film of Palladium Gold to reduce charging.

MS03 AJA 1500 Magnetron Sputter Deposition

The ATC 1500 sputter deposition system, by AJA International, has the capability to co-sputter conductive and insulating materials on substrates up to 100 mm in diameter. In addition to Ar sputtering, N2 and O2 are also available for use in reactive-ion sputtering. The UTD object is equipped with 2 RF and 2 DC magnetron sources with in-situ tilt capability to optimize film uniformity. The substrate is capable of heating to 800 C while under rotation as well as exposure to reactive gasses and RF bias. Software for control of the various source shutters is also available for automated film stack deposition.

Process Data

Control Charts

MS04 AJA Orion Magnetron Sputter Deposition

The ATC Orion sputter deposition system, by AJA International, has the capability to co-sputter conductive and insulating materials on substrates up to 100 mm in diameter. In addition to Ar sputtering, N2 or O2 are also available for use in reactive-ion sputtering. The UTD object is equipped with 3 RF and 2 DC magnetron sources. The substrate is capable of heating to 800 C while under rotation as well as exposure to reactive gasses and RF bias. Software for control of the various source shutters is also available for automated film stack deposition.

Process Data

Control Charts

TC03 PICOSUN R-200 Advanced Plasma ALD–COMING Fall 2020

For metal and metal nitride deposition…coming fall 2020